Self-Tapping Screws and Australian AS3566 Standard

Self-tapping screws that can tap their own thread into a pre-drilled hole are a specific type of fastener designed for applications where precision and reliability are essential. These screws are particularly useful in scenarios where the material being fastened is harder or where tight tolerances are required.

Key Features of Self-Tapping Screws:

- Thread Design:

Self-tapping screws that are designed to thread into pre-drilled holes have threads that are carefully engineered to create a secure grip as they cut into the material. Typically, these screws feature finer threads that are optimized for tapping into the material efficiently without causing damage. - Pointed Tip:

These screws usually feature a pointed tip, allowing for easy insertion into the pre-drilled hole. The tip may have a slight taper to ensure a smooth entry and reduce the likelihood of misalignment during application. - Material Composition:

Self-tapping screws are generally made from high-quality steel or stainless steel. Many are treated with protective coatings, such as zinc plating, to enhance their corrosion resistance and durability, particularly in environments exposed to moisture or harsh conditions. - Head Styles:

They come in a variety of head styles, including pan head, flat head, and truss head, allowing versatility in installation based on the desired aesthetic and functional requirements. - Applications:

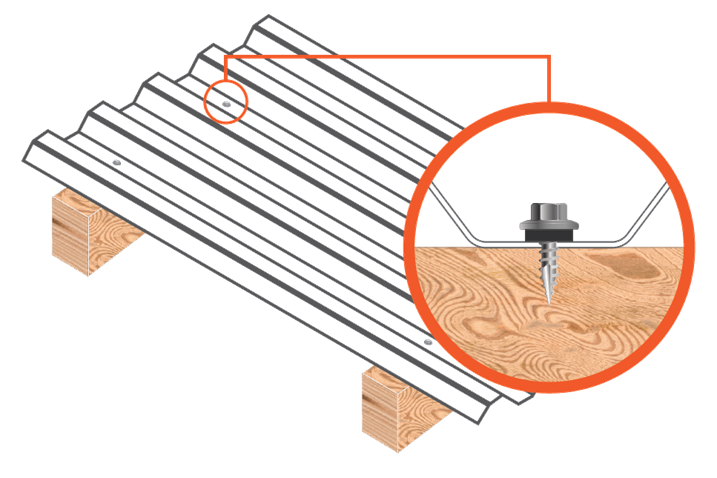

These screws are widely used in metalworking, woodworking, and assembly applications where precise fastening is needed, such as attaching metal components, securing drywall, and in the fabrication of furniture. They are particularly beneficial when working with materials that may split or crack if directly driven without pre-drilled holes.

Compliance with Australian AS3566 Standard:

The Australian AS3566 Standard provides guidelines for the manufacturing and performance of self-tapping screws, including those that tap into pre-drilled holes. Key aspects of this standard include:

- Material Quality:

Self-drilling screws are typically made from carbon steel, stainless steel, or alloy steel because this choice of material affects the screw’s strength and corrosion resistance. BoldTech self-drilling screws manufactured under the AS3566 standard are made from high-quality materials that meet specific mechanical properties to ensure adequate strength and performance. Additionally, stainless steel screws offer excellent corrosion resistance, making them suitable for outdoor or humid environments. - Corrosion Resistance:

The standard dictates requirements for corrosion resistance to ensure that screws can withstand the harsh Australian environment, including exposure to moisture, salt, and other corrosive elements. Ruspert coating is a specialized surface treatment for BoldTech Fasteners, designed to provide exceptional corrosion resistance, as proven by its ability to withstand up to 2,000 hours in a salt spray test. This multi-layered coating system enhances the durability and lifespan of metal components, particularly in harsh environments. - Performance Testing Protocols:

AS3566 outlines the necessary testing protocols for evaluating the performance of self-tapping screws, including tests for dimensional accuracy, tensile strength, and resistance to stripping or breakage. These assessments ensure that the screws will perform reliably in their intended applications. - Design Specifications:

The standard provides detailed specifications for the design of self-tapping screws, including necessary thread forms, head configurations, and physical dimensions. This ensures that the screws can be effectively used across different materials and installation methods.